Resins for injection

You are in: Civil construction > Land consolidation > Resins for injection

Resins

Material for injection

StekoX@ Polyurethane resin for injection

Resins for injection

Resin for injection of high quality and low viscosity for sealing cracks, horizontal blocks and injections by injected tube.

The resin for injection is elastic and can come into contact with drinking water (Certified check).

Make a previous injection of polyurethane foam resin StekoX @ to water pressure and / or normal water flows.

Properties of Resins for injection

Polyurethane Resin of two component

No solvents

Mixing ratio 1: 1 volume ratio

Temperature field > + 5' C

2 hours period of application (1 R, 20°C)

Catalyzing StekoX@ B 14

Ideal equipment Cleaner StekoX@ A y B

StekoX@ foaming polyurethane resin for injection

Foaming polyurethane resin for injection reactive to moisture to seal cracks and leaks that are under pressure and by passing water.

The Injection foam resin foamy quickly and can increase 30 to 50 times its volume. Also suitable for application in areas of drinking water (test certificate).

For permanent sealing is required subsequent injection of polyurethane resin for injection StekoX @.

Properties

Foaming polyurethane resin S

Mix 1 component

Viscosity 1200 ± 100 mPas

Temperature range 0 -40°C

Application period Reaction begins upon contact with water

Expansion starts approx. 30 s after contact with water - If necessary, the reaction can be catalyzed with stekoX @ ADDX.

Appropriate cleaner Cleaner stekoX@ B

StekoX@ Cleaner

Resins for injection. StekoX@ Cleaner A

Cleaner pumps and devices with great strength solvent. Suitable for @ StekoX all resins in a fluid state and not hardened. solvent organic mixture, fuel and colorless.

Resins for injection. StekoX@ Cleaner B

Powerfully Cleaner to take off and swollen hardened foam resin for injection eg. Organic solvent, fuel and colorless.

FOR TUNNELS AND CIVIL ENGINEERING SX FOAM RESIN PUR

Applications of Resins for Injection

Reacts with water is a single component with integrated catalyst, free of CFCs. Ready to use without mixing:

For the water flows

For consolidation

Tunnels

Application at ambient temperatures between O and 40 ° C

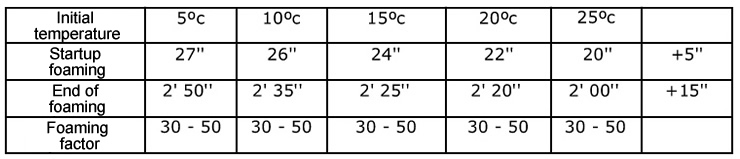

Reaction data

Average reaction time measured with 10% added water.

If necessary, the reaction can be accelerated by the catalyst PUR.

The above data are tested in laboratory. May vary in practice depending on the properties of the stone, humidity, pressure, among other factors.

Properties of resins for injection

Properties and composition of resins for injection

SX consists of "isocionate" modified softeners and additives.

Applications of Resins for Injection

SX reacts with water. Therefore in open containers may be formed as a skin on the liquid surface by reaction with moisture in the air, which does not affect the operating time.

SX is injected as a single component through the use of packers with a manual pump or an engine in the affected areas. When contacted with water, the reaction so that foam hardens. If the zone

to be sealed is not enough water can harden the resin.

Recomendations for Resins for Injection

We recommend to store the product first at a temperature of 15 ° C for 12 hours in order to achieve the proper temperature between 15 to 30 º C.

Safe Handling Information for Resins for Injection

Protection using gloves and glasses, do not inhale ...

After contact with skin or eyes, wash with water and go see the doctor.