Xypex® Patch'n Plug.

Concrete Waterproofing

You are in: Building construction > Waterproofing for party walls > Xypex® Patch'n Plug Concrete Waterproofing by crystallization

Xypex® Patch'n Plug

Concrete Waterproofing by Crystallization

DESCRIPTION

XYPEX ® Concrete Waterproofing by crystallization

Xypex Patch'n Plug is a specially designed, fast-setting, non-shrink, high-bond-strength, hydraulic cement compound for concrete patching and repair. Patch’n Plug stops flowing water in seconds and is used to seal cracks, tie holes, and other defects in concrete. The high performance characteristics of Patch’n Plug are enhanced by Xypex’s unique crystalline waterproofing technology.

PRESENTATION

Xypex Patch'n Plug, Concrete waterproofing, is available in 9.1 kg pails and 60 27.2 kg pails.

STORAGE

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is one year when stored under proper conditions.

COVERAGE

One 27.2 kg pail of Xypex Patch’n Plug will produce 0.0154 cu. metres of mortar.

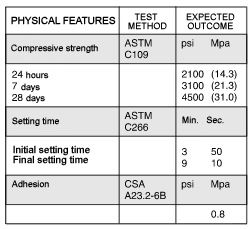

TEST RESULTS

Note: Samples prepared with 1 part water to 3.25 parts dry powder by volume (1 part water to 4 parts dry powder by mass). Setting time was determined using Gilmore needles.

RECOMMENDED FOR

Stop leaks or high pressure water incomes

Repair cracks in concrete

Repair and sealing Hs / He joints

Anchors

Added to mortars or concrete repair, accelerate setting

ADVANTAGES

Only requires mixing with water

Quick setting of 2 to 3 minutes with a temperature of 21 BC

Excellent structural strength

Durable as concrete or masonry to which is applied

It contains no metal parts

No rust or deteriorate

Non-toxic

PLUGGING INSTRUCTIONS

1. Concrete waterproofing. Preparation

Rout out crack or hole by chiseling or chipping to a minimum depth of one inch (25 mm). Form a square or dovetail shaped space (do not use a “V” cut). Flush away all loose materials and dirt from the cavity with water and a stiff brush.

2. Concrete waterproofing. Mixing

Add 1 part water to 3.5 parts Patch’n Plug by volume and mix to the consistency of a stiff putty. Do not mix more than can be used in 3 minutes. For best results, water temperature should be approximately 60ºF - 70ºF (15ºC - 20ºC).

3. Concrete waterproofing. Tamponade

3. Plugging form plug with gloved hand. Place plug into cavity pressing firmly until plug is hard. When sealing cracks, begin at the highest point and work down. Where there is a high water pressure flow, form mastic with rubber gloves and wait until it is almost hard before bring it into the water flow, then press down firmly until mastic it has hardened completely (3 min.).

Concrete waterproofing. Sealing against high water flow

NOTE: Where there is a high volume of water flow due to extreme hydrostatic pressure, follow these steps: With a concrete chisel and hammer (or chipping gun), cut open a cavity at the point of greatest water flow.

a) Place a stiff section of hose or pipe into the cavity and secure in place with Patch’n Plug to force water through the hose. This relieves the pressure so that the area can be patched. Allow a minimum of 24 hours for hardening.

b) Remove bleeder hose and plug remaining hole. If necessary, reduce water flow by inserting steel wool or wooden plug in the remaining hole before patching.

TECHNICAL SERVICES FOR XYPEX PATCH'N PLUG, CONCRETE WATERPROOFING

For more instructions, alternative application methods, or information concerning the compatibility of the Xypex treatment with other products or technologies, contact the Technical Services Department of Xypex Chemical Corporation or your local Xypex representative.

SAFE HANDLING INFORMATION

Xypex is alkaline. As a cementitious powder or mixture, Xypex may cause significant skin and eye irritation. Directions for treating these problems are clearly detailed on all Xypex pails and packaging. The Manufacturer also maintains comprehensive and up-to-date Material Safety Data Sheets on all its products. Each sheet contains health and safety information for the protection of workers and customers. The Manufacturer recommends you contact Xypex Chemical corporation or your local Xypex representative to obtain copies of Material Safety Data Sheets prior to product storage or use.

XYPEX PATCH'N PLUG WARRANTY. CONCRETE WATERPROOFING

The Manufacturer warrants that the products manufactured by it shall be free from material defects and will be consistent with its normal high quality. Should any of the products be proven defective, the liability to the Manufacturer shall be limited to replacement of the product ex factory. The Manufacturer makes no warranty as to merchantability or fitness for a particular purpose and this warranty is in lieu of all other warranties expressed or implied. The user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith.